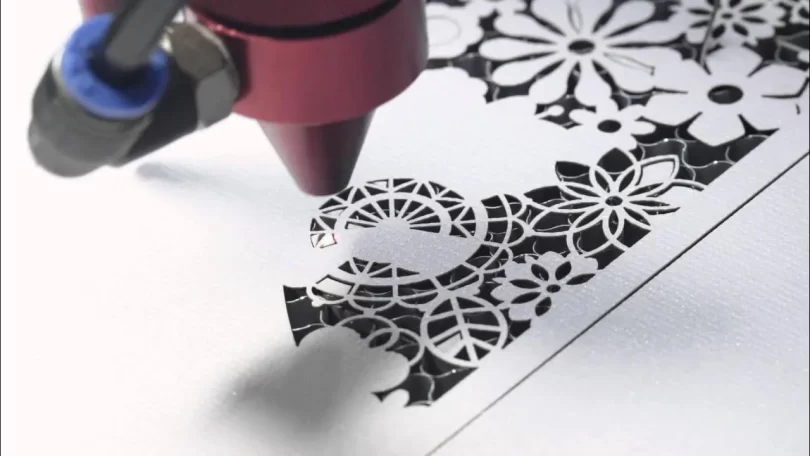

Laser cutting has revolutionized the way we work with paper, offering precision and versatility that traditional methods simply can’t match. Whether you’re a hobbyist creating intricate greeting cards or a professional designing packaging prototypes, a laser machine can provide clean, detailed cuts with minimal effort. This guide will walk you through everything you need to know about laser cutting paper, from choosing the right materials to optimizing your machine settings for the best results.

Understanding Laser Cutting for Paper

Laser cutting uses a high-powered laser beam to cut, engrave, or etch materials with extreme accuracy. Unlike manual cutting tools or die-cutting machines, laser cutters allow for complex designs and fine details without the risk of fraying or tearing.

There are various types of laser cutters, but for paper, CO2 lasers are the most common. These machines provide the right balance of power and precision needed for delicate materials like cardstock, vellum, and specialty papers.

Choosing the Right Paper for Laser Cutting

The type of paper you choose significantly impacts the quality of your cuts. Here are a few key considerations:

- Thickness: Lighter papers cut easily but may curl; heavier cardstock provides sturdier results.

- Texture: Smooth paper works best for clean cuts, while textured paper may require adjustments to settings.

- Coating: Avoid glossy or laminated papers, as they can produce excess burn marks or unwanted residue.

Recommended options include high-quality cardstock, kraft paper, and fine art paper. Avoid coated or plastic-based papers that can release harmful fumes when cut.

Setting Up Your Laser Cutter

To achieve the best results, setting up your laser cutter properly is essential. Key settings include:

- Power: Low to medium power is ideal for paper to prevent scorching.

- Speed: Higher speeds help reduce burning and maintain clean edges.

- Frequency: Adjusting the pulse rate of the laser can improve precision on intricate designs.

If you’re looking for a reliable laser cutter for paper projects, a CO2 laser cutting machine from OMTech is a solid choice. Their machines offer a good balance of power and control, making them ideal for cutting fine details in paper without excessive burning. Additionally, they provide accessible options for both beginners and experienced users.

Tips for Achieving Clean Cuts

Laser-cutting paper requires some fine-tuning to get perfect results. Here are a few tips:

- Use air assist: This helps blow away debris and prevents burn marks.

- Test settings on scrap paper: Every paper type reacts differently, so always do a test cut.

- Ensure proper ventilation: While paper doesn’t produce a lot of fumes, airflow helps maintain consistency in cuts.

Creative Applications of Laser-Cut Paper

Laser-cut paper is used in a variety of creative fields, including:

- Custom invitations & greeting cards: Perfect for weddings, birthdays, and corporate events.

- Stencils & templates: Useful for painting, crafting, and design work.

- Paper sculptures & decorations: From intricate 3D models to delicate paper art.

- Branded packaging: Adds a unique touch to product presentation.

Troubleshooting Common Issues

Despite the precision of laser cutting, some common issues may arise:

- Burn marks: Reduce power settings or increase speed to minimize scorching.

- Paper catching fire: Lower the power and use air assist to prevent excessive heat buildup.

- Incomplete cuts: Increase the power slightly or slow down the speed for thicker papers.

Conclusion

Laser cutting paper opens up endless creative possibilities, whether for personal projects or professional work. By selecting the right paper, fine-tuning your machine settings, and experimenting with different designs, you can achieve beautifully detailed results. If you’re considering investing in a laser cutter, starting with a well-balanced CO2 machine like OMTech’s can make the process smoother, offering both precision and versatility. Now, it’s time to bring your creative ideas to life!