The farm-to-fork principle has always been associated with the freshness of locally-grown foods delivered straight to the dining room; proximity established a short and quick supply chain.

Luckily, the supply chain now ensures safe delivery of temperature-dependent produce regardless of the time of the day or locations (even the continents); however, its foundation has changed to digital solutions, like SAP ERP modules, specialized vehicles, and insulating materials. When combined together, they create an ideal and protected environment for delivering temperature-dependent goods to the end-users. Let’s see how it works.

Contents

What Is Cold Logistics?

Cold chain logistics refers to a specifically organized routing of temperature-sensitive goods throughout the supply chain, ensuring the conditions of the transportation environment maintain stable temperatures to preserve the quality and integrity of the goods. Cold logistics is mainly applied to food items, medicine (vaccines, temperature-dependent pills), plants, beverages, biotech products, etc.

A supply chain alone is always a complexity of actions that are performed to ensure safe and sound end-to-end delivery of goods. With cold chain logistics, the stakes get higher, as every delay only induces the perishable processes, leading to dissatisfied users, financial losses, disruption of production, etc. Therefore, there is a need for high-tech solutions (powered by AI) to provide an impeccable end-to-end movement of goods without the loss of quality.

One of the pillars of cold logistics efficiency is the warehouse and its management, as it’s the heartbeat of the whole supply chain. Aiming for transparency and visibility within the warehouse, there is a need for solutions like SAP for Warehouse Management (SAP WM) to provide complete visibility of the process. Implementing SAP solutions is necessary, as it makes the whole idea of cold chain logistics possible.

Here, you can find all the informational support regarding the supply logistics and the most viable solutions for it. The team of professionals from LeverX, an international company with decent expertise in SAP integration, will help you choose proper solutions regarding your current and forthcoming needs.

Key Components of Cold Chain Logistics

1. Temperature monitoring

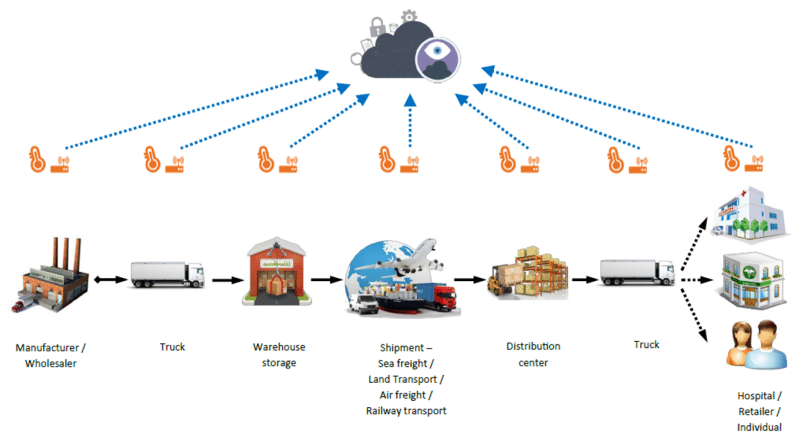

The right temperature is essential for keeping the products functioning without sacrificing their quality. Temperature is regulated by using specific monitoring devices placed in every specific supply chain location to record and control the temperature regimen continuously. When the system notices the deviation from the set standard, it notifies those who are in charge, allowing them to make timely and proactive regulatory decisions.

2. Packaging and Insulation

Packaging is vital when ensuring the safety and temperature regimen of the goods, as it creates a thermal barrier between the goods and the external temperature sources. Packaging materials typically include expanded polystyrene foam and vacuum-insulated panels, as they provide high-quality insulation, minimize physical damage, and prevent moisture ingress.

3. Transportation and storage

Monitored and controlled transportation is essential for preserving quality of the temperature-sensitive goods. The specialized vehicles, also called reefers, are equipped with a temperature control system to maintain the right temperature level along the way. The reefers and storage facilities are powered by advanced freezing technologies like mechanical and/or cryogenic systems.

The storage facilities may be designed for a particular type of temperature and goods or may be divided into specific chambers and temperature zones to accommodate various products, providing optimal conditions.

Tech-Powered Solutions for Cold Chain Logistics

Order fulfillment

Technology influences the cold chain immediately upon getting the customer orders. The initial stage includes picking, packing, and preparing temperature-sensitive goods for shipment with the help of temperature-controlling materials.

Efficient route planning regarding distance, temperature requirements and fluctuations, and delivery time-frames are crucial for preserving the quality and integrity of produce when reaching the end-user.

Inventory management

Inventory management helps optimize the stock levels, prevent the products from getting rotten, and minimize overall waste. Inventory management digital solutions, like SAP EWM (extended warehouse management), provide tools to conduct wireless inventory management and gain real-time access to stock replenishment, temperature-related data, and product quality.

Tracking

The supply chain requires complete visibility into every type of activity or interaction. The tracking systems to be used are:

- Global Positioning System – GPS

- Global system for mobile communication – GSM

- Radiofrequency identification – RFID

- Bluetooth low-energy – BLE

The real-time data is sent to a specific business solution, like SAP EWM, and thus, the customers get 24/7 access to the tracking information, with the opportunity to keep control over the whole process and make necessary changes.

Monitoring

The monitoring system includes control over temperature, humidity, and vibration (in case the product is fragile):

- Data loggers – devices placed within the storage area measure temperature and humidity at regular intervals. Data loggers keep records of conditions, which can be accessed through a physical connection to a data logger.

- Bluetooth temperature sensors – the devices that measure the temperature, humidity, and location. The records are sent through wifi and can easily be reached by smartphone scanner.

- IoT – The Internet of Things – provides real-data monitoring and measurement at programmed intervals.

- Bluetooth sensors get to read the data → A portable gateway collects it and transmits it to the virtual storage → Cloud storage processes data and visualizes it through specialized business platforms (SAP EWR, SAP ERP).

Numerous points of data and their non-stop reports into the centralized system empower the managers with 24/7 visibility into the cold logistics chain and provide an uninterrupted flow of goods.

The Takeaways

- Cold logistics is the most advanced form of end-to-end transportation of temperature-sensitive goods.

- Considering how critical the temperature environment is, proper scheduling, timing, and visibility into the process are the cornerstones of successful supply chain cycles.

- Cold chain logistics bears no delays and cancelations, leading to the integrity decay of the goods and colossal financial losses.

- Cold chain supply is based on the usage of high-tech solutions, like SAP ERP modules, which give complete visibility into the supply chain and can be integrated with other monitoring solutions to create an interconnected company infrastructure with a highly efficient workflow. Contact the LeverX developers and get a chance to boost the performance of your cold chain logistics.